DQ270T MODIFIED ATMOSPHERE PACKAGING MACHINE

DQ270T table top MAP tray sealing machine Dasen manufactured, is widely used for food distribution in supermarkets such as fresh meat, cooked meat products, fish, poultry, shellfish, fruits, coffee, tea, vegetables, bread, etc. Modified atmosphere packaging has the characteristics of keeping food quality, freshness, color, shape and taste, and is popular in European and American markets.

* Molds customized for the popular tray sizes in your territory for your marketing penetrating, with free charge.

* Modified atmosphere packaging to extend shelf life, outlook and taste retention.

* Real-time fault indication, enable quick adjustment and after-sales service.

* Stainless steel and anti-corrosive aluminum construction.

* Teflon coated sealing plate, easy maintenance if film melt and sticked.

* Sealing temp/time, film and other parameters can be easily adjusted on touch screen controller.

* Easy to operate, and neat profile cutting and sealing of film, pneumatic drive.

* Precise and automatic film feeding with photoelectric and disc sensors.

* Safety and sliding mold design, and easy changeover without tools.

* Safe and hygienic, CE certification.

* Supply training video and after-sales service online with quick response.

* Voltage/plug type can be customized as required. WITT gas mixer optional.

* Package material: trays made from Degradable pulp box/ PP / PET/Aluminum foil, and we could supply tray+film according to your size and print if needed.

Expertise sales manager ready for helping to prompt your business:

We are a reliable Chinese manufacturer with good quality and ODM OEM business are welcome!

If you order more than 5pcs, there will be more competitive prices and marketing support.

| Technical parameter | Airflow type |

| Equipment model | DQ270T-E |

| Maximum width of roll film (mm) | 260 |

| Maximum diameter of roll film (mm) | 200 |

| Capacity (box/hour) output 1 | ≈360 |

| Capacity (box/hour) output 2 | ≈640 |

| Capacity (box/hour) output 4 | —— |

| Power supply (v/hz) | 220/50 |

| Total power (kw) | 1.5 |

| Working air pressure (Mpa) | 0.6~0.8 |

| Equipment weight (kg) | 60 |

| Equipment size L × W × H(mm) | 680×580×750 |

| Gross weight of package (kg) | 70 |

| Packing box size L × W × H(mm) | 700×540×860 |

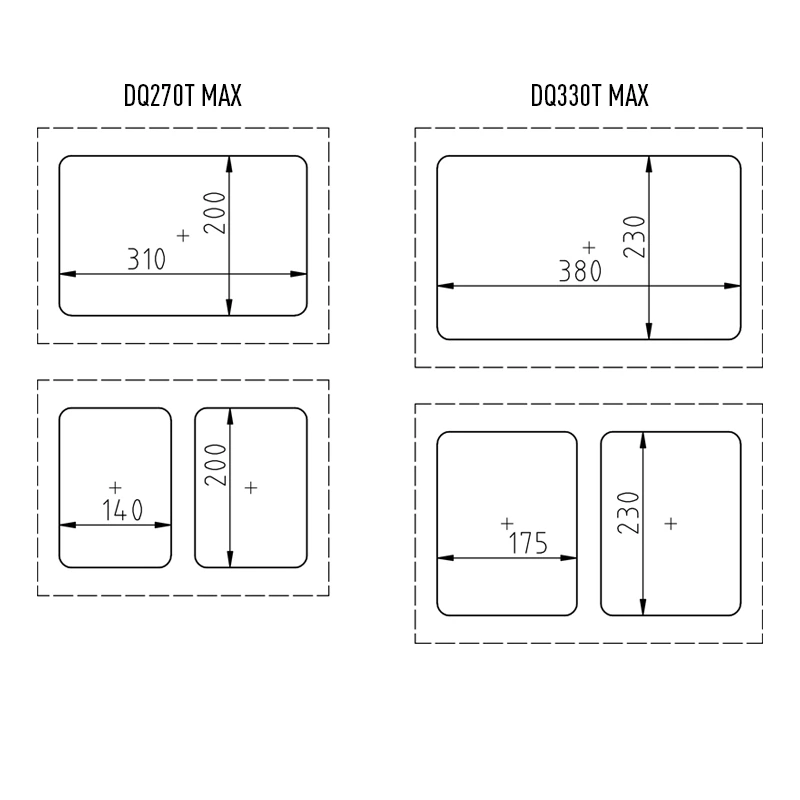

| Maximum size of tray (mm) out of 1 | 310×220×60(x1) |

| Maximum size of tray (mm) out of 2 | 220×140×60(x2) |