DQ240VST DESKTOP VACUUM SKIN PACKAGING MACHINE

DQ240VST vacuum skin packaging machine from Dasen factory, is suitable for fresh meat, fruits and vegetables, seafood and other foods. There are different models of machines, and stores or factories can choose them according to their needs. The equipment need less room, and can be easily operated. The main structure of the product is made of stainless steel, and the vacuum chamber is anodized with 6061, which is safe and sanitary. By pumping dry air through the machine, the food can be kept in a vacuum state to prolong the fresh-keeping time. The skin-fitting effect is beautiful and practical, so as to prompt consumers purchasing. According to different production requirements, Zhejiang Dasheng Intelligent Equipment Co., Ltd. can tailor-make the skin-fitting packaging equipment, and help distributors sell the machines to end users.

* Prolong shelf life, outlook and taste retention.

* Real appearance display in supermarket, more attractive to consumers.

* Can be heated in microwave oven.

* Real-time fault indication, enable quick problem solving and after-sales service.

* Stainless steel 304 and anti-corrosive aluminum construction.

* Teflon coated sealing plate, easy maintenance if film melt and sticked.

* Vacuum pump built-in and visible adjustment on vacuum gauge.

* No need specified mold, while film cutting by hand.

* Safe and hygienic, CE certification.

* Supply training video and after-sales service online with quick response.

* Voltage/plug type can be customized as required. BUSCH vacuum pump optional.

* Package material: trays made from PP / PET, and we could supply tray+film according to your size and print if needed.

Expertise sales manager ready for helping to prompt your business:

We are a reliable manufacturer with good quality and ODM OEM business are welcome!

If you order more than 5pcs, there will be more competitive prices and marketing support.

| Technical parameter | VACUUM SKIN PACKAGING MACHINE | ||

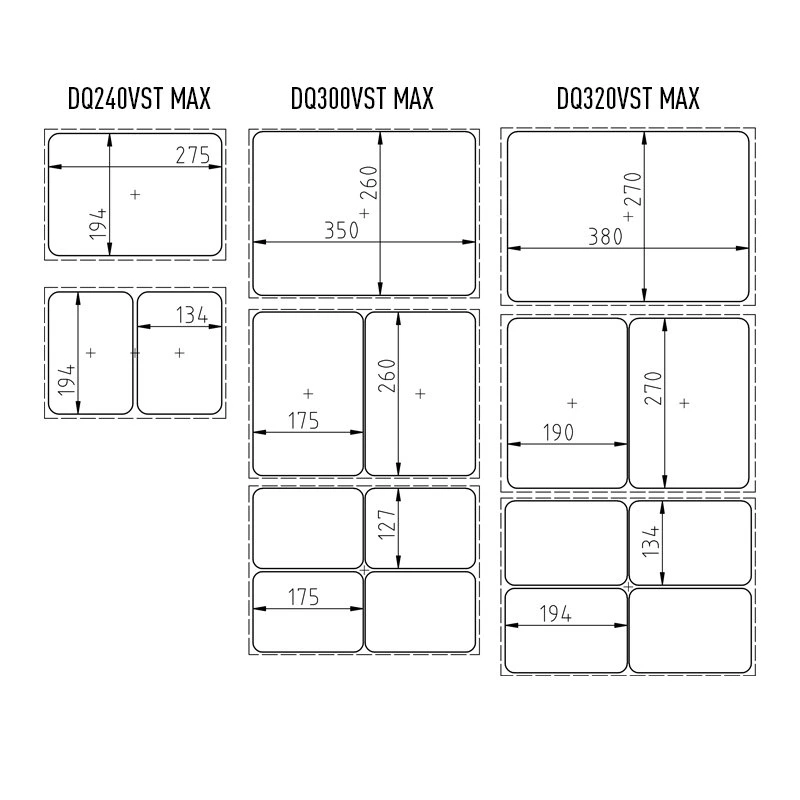

| Equipment model | DQ240VST | DQ300VST | DQ320VST |

| Maximum width of roll film (mm) | 250 | 305 | 320 |

| Maximum diameter of roll film (mm) | 180 | 180 | 180 |

| Capacity (box/hour) output 1 | ≈120 | ≈120 | ≈120 |

| Capacity (box/hour) output 2 | ≈240 | ≈240 | ≈240 |

| Displacement of vacuum pump (m3/h) | 10 | 20 | 20 |

| Power supply (v/hz) | 220/50 | 220/50 | 220/50 |

| Total power (kw) | 2.2 | 2.5 | 2.5 |

| Working air pressure (Mpa) | —— | —— | —— |

| Equipment weight (kg) | 36 | 53 | 58 |

| Equipment size L × W × H(mm) | 490×380×430 | 600×430×430 | 600×430×430 |

| Gross weight of package (kg) | 45 | 65 | 72 |

| Packing box size L × W × H(mm) | 600×420×550 | 680×520×540 | 680×520×540 |

| Maximum size of tray (mm) out of 1 | 270×180×60 | 390×270×60 | 410×280×60 |

| Maximum size of tray (mm) out of 2 | 200×140×60 | 270×180×60 | 280×185×60 |